YOUR CHANCE!

Your solution to the shortage of skilled workers and the global price war.

Without programming to the finished component.

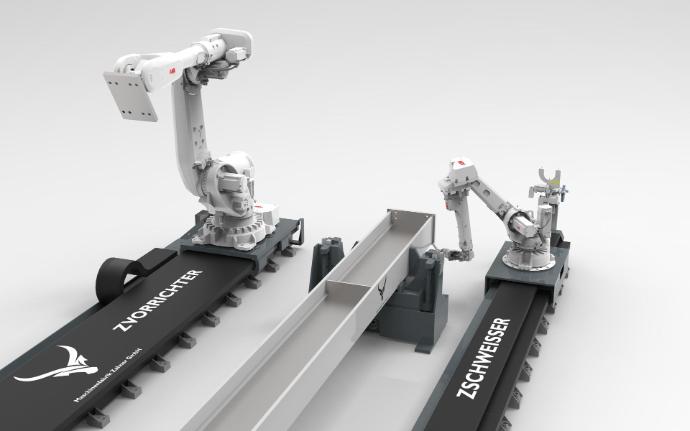

ZSCHWEISSER - The revolution in steel construction

Efficient. Precise. Automatically.

The ZSCHWEISSER is a pioneering robot solution for the steel construction industry. This innovative welding robot sets new standards in manufacturing and makes the production process easier than ever before.

Direct CAD data transfer:

Import your design data directly from your CAD system to the ZSCHWEISSER. The robot automatically assembles, welds and removes weld spatter - precisely and without any manual programming.

Flexibility without CAD:

No CAD? No problem! Thanks to the integrated 3D scan technology, the ZSCHWEISSER recognizes the component to be welded, analyses it and displays it in the operating area. Now all you have to do is select the weld seam size - the machine carries out all other processes completely automatically.

Expandable for maximum efficiency:

- Rotary units: For complex geometries and precise handling.

- Pre-rigging robot: Facilitate and optimize assembly.

- Needle scaler: Efficiently removes welding spatter and ensures perfect surface quality.

Automated workflow:

From planning to the finished component - the ZSCHWEISSER does everything in one continuous work process. Whether you are producing a single component or large-scale projects, this system enables you to achieve maximum precision and productivity.

ZSCHWEISSER-S

For simple and small assemblies.

ZSCHWEISSER-P

For all applications, the robot can reach any location thanks to the range of the gantry.

ZSCHWEISSER-G

Für Brücken oder Schiffsbau ist unsere Gantrylösung die erste Wahl.

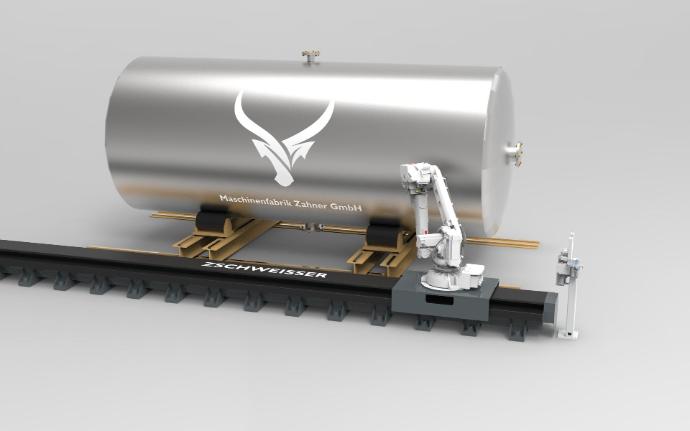

ZSCHWEISSER-Container and tank construction

Solutions as a portal or rail solution.

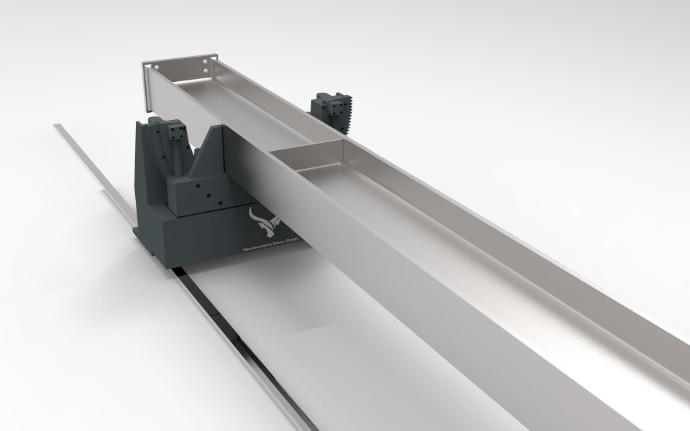

ROTARY UNITS

Thanks to our rotating units, the steel beams can be moved into any position.